Portions of roof structures not covered with photovoltaic panel systems shall be designed for dead loads and roof loads in accordance with section r301 4 and r301 6.

Solar panel dead load for future use.

For a roof live load or snow load in some areas of the country it s a sum of approximately 30 pounds per square foot.

An additional superimposed dead load allowance of 0 25 kpa should be used in the design of the roofing.

This is the sum of a 20 pounds per square foot dead load including a ballasted membrane roof which was typical for roofs on shopping centers in the early 1980s for example.

Roof loads and solar energy.

For example the weight per square footing for asphalt shingle weight per 100sq ft lbs range is 190 250.

For a roof live load or snow load in some areas of the country it s a sum of approximately 30.

Although this point load force may appear very small consider that 30 pounds is a 12 5 percent increase of total dead load 240 lbs on a 16 foot long rafter without solar panels.

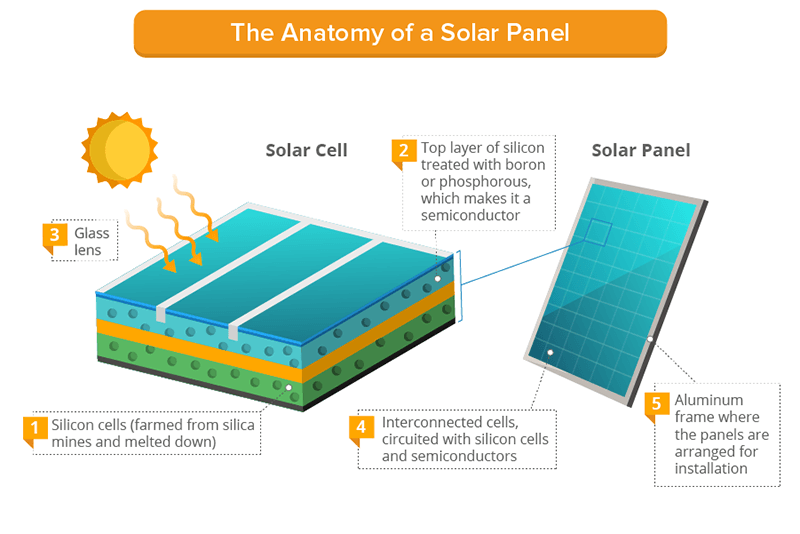

Solar modules panels.

Therefore a typical roof with 24 inch rafter spacing and rafters that weight 2 plf would have a dead load of 10 x 24 12 2 22 plf before the solar equipment was added.

To make the.

How big are solar panels.

Structural engineers use the solar panel roof load calculator to come up with the correct load capacity of the roof material.

Roof structures that provide support for photovoltaic panel systems shall be designed for live load lr for the load case where the photovoltaic panel system is not present.

This is the sum of a 20 pounds per square foot dead load including a ballasted membrane roof which was typical for roofs on shopping centers in the early 1980s for example.

The average size of solar panels used in a rooftop solar installation is approximately 65 inches by 39 inches or 5 4 feet by 3 25 feet there is some variation from brand to brand and if you re installing a large scale solar panel system such as for a warehouse or a municipal building your panels will be closer to 6 feet long.

A majority of roofs can withstand the weight of solar panels.

For a 16 foot rafter this then results in a 352 lbs.

Their proof of concept technology is a hexagonal road panel that has a glass driving surface with underlying solar cells electronics and sensors to act as a part of solar array with programmable capability.

Solar roadways incorporated is an american company based in sandpoint idaho aiming to develop solar powered road panels to form a smart highway.

If 6 base mounts for 3 rows of panels were to be concentrated on one such rafter weight of solar panels 180 lbs would increase dead load by 75 percent.