For many panels this is given as 2 to 3 in the first year and then 0 7 a year after that but it can be as low as 0 25 a year for some sunpower panels.

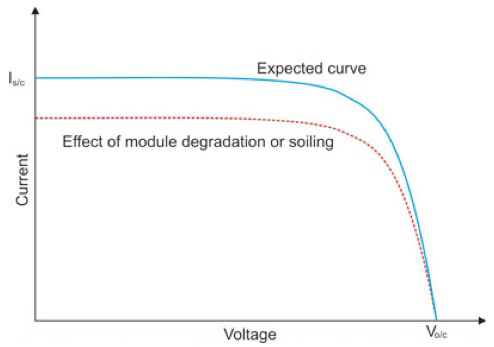

Solar panel degradation curve.

It s a good idea not to get these percentages confused.

Note these figures may have a minus sign in front of them as in 0 7 or 0 25.

By keeping the solar cell very thin i e by choosing an i layer thickness d i in the range of 200 300 nm and by adopting all the other measures described earlier see section 2 1 one is able today to fabricate amorphous silicon solar cells with a relative.

In addition degradation rates for 10 selected systems were found to be larger than 1 year.

A meta analysis of 11 000 solar power installations found that the median degradation rate was 0 5 to 0 6 meaning for every panel that declined more slowly another declined more quickly.

As an example let s assume the following about our solar system.

The worst degradation rate is 80 a year but as a benchmark you can expect an average degradation rate of 50 a year for any panel.

In 1977 the department of energy established the solar energy research institute in golden colorado.

Reported on block iv and v monocrystalline si systems deployed in florida and found degradation rates well below 1 year 32.

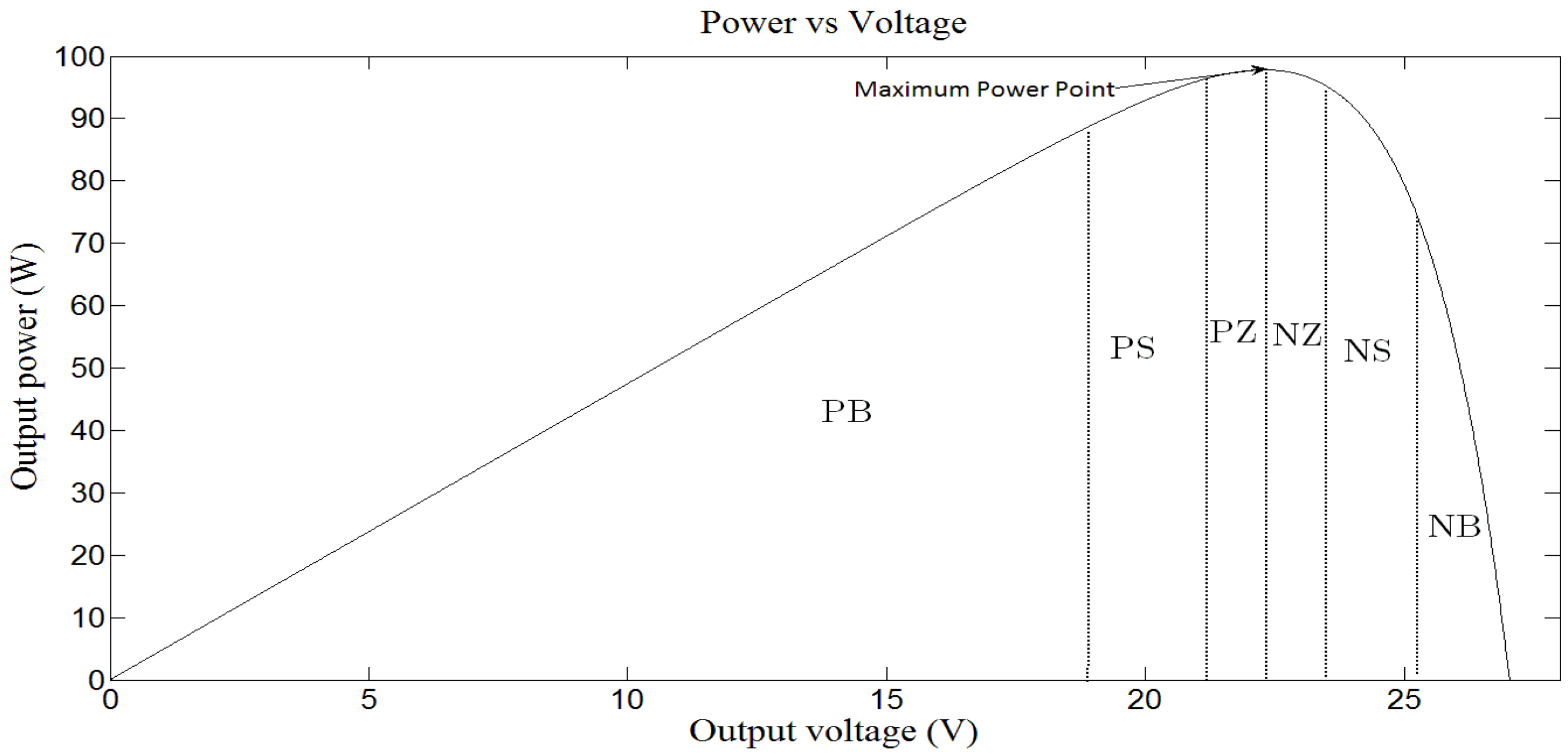

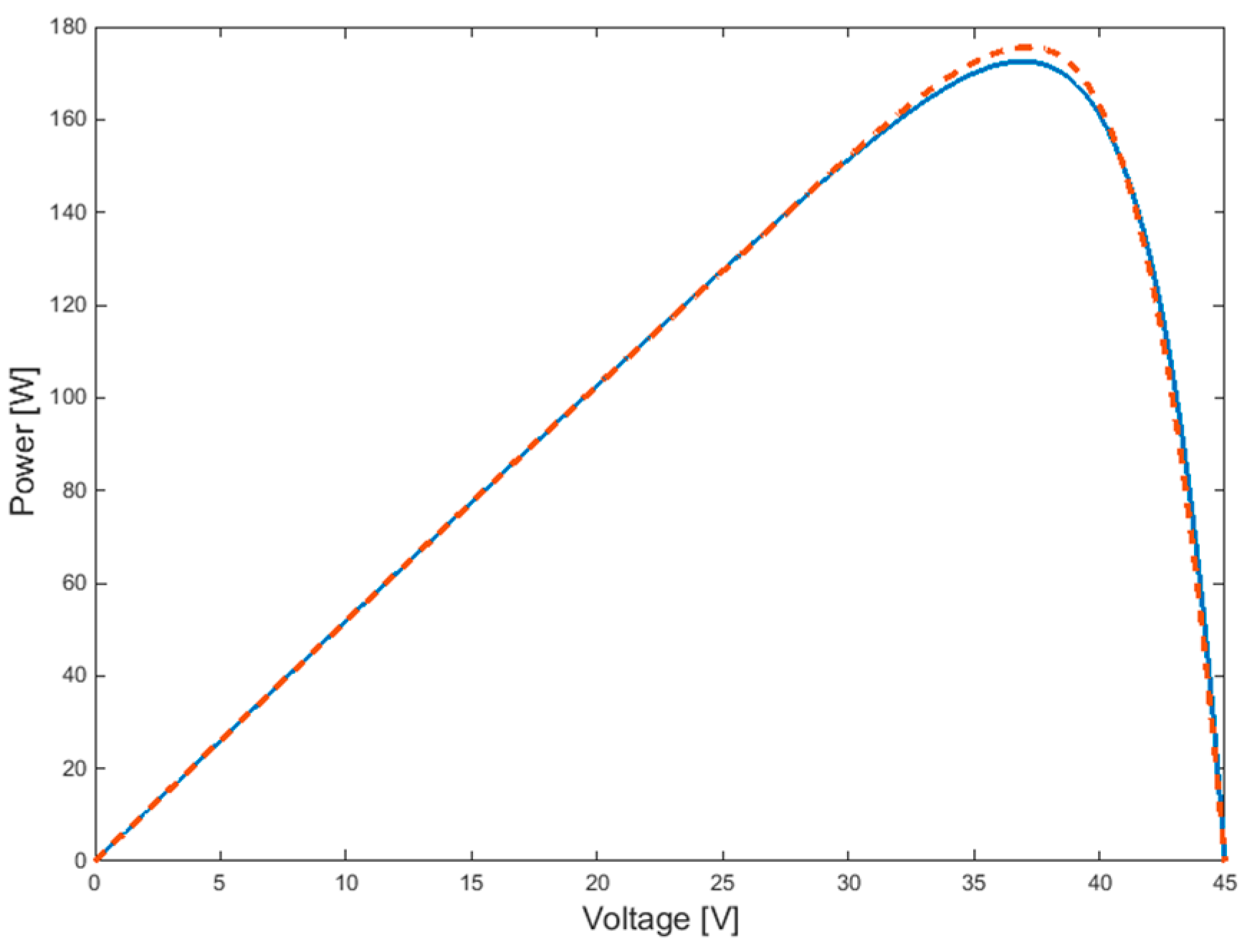

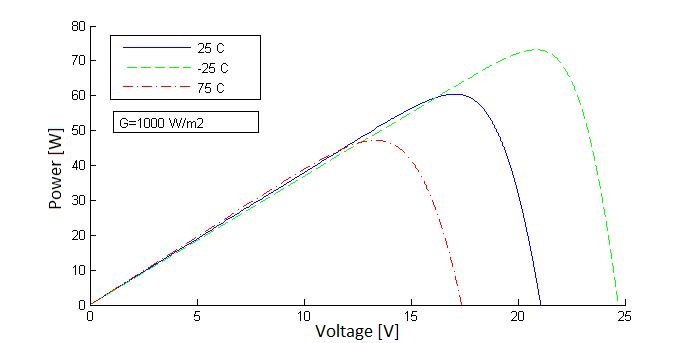

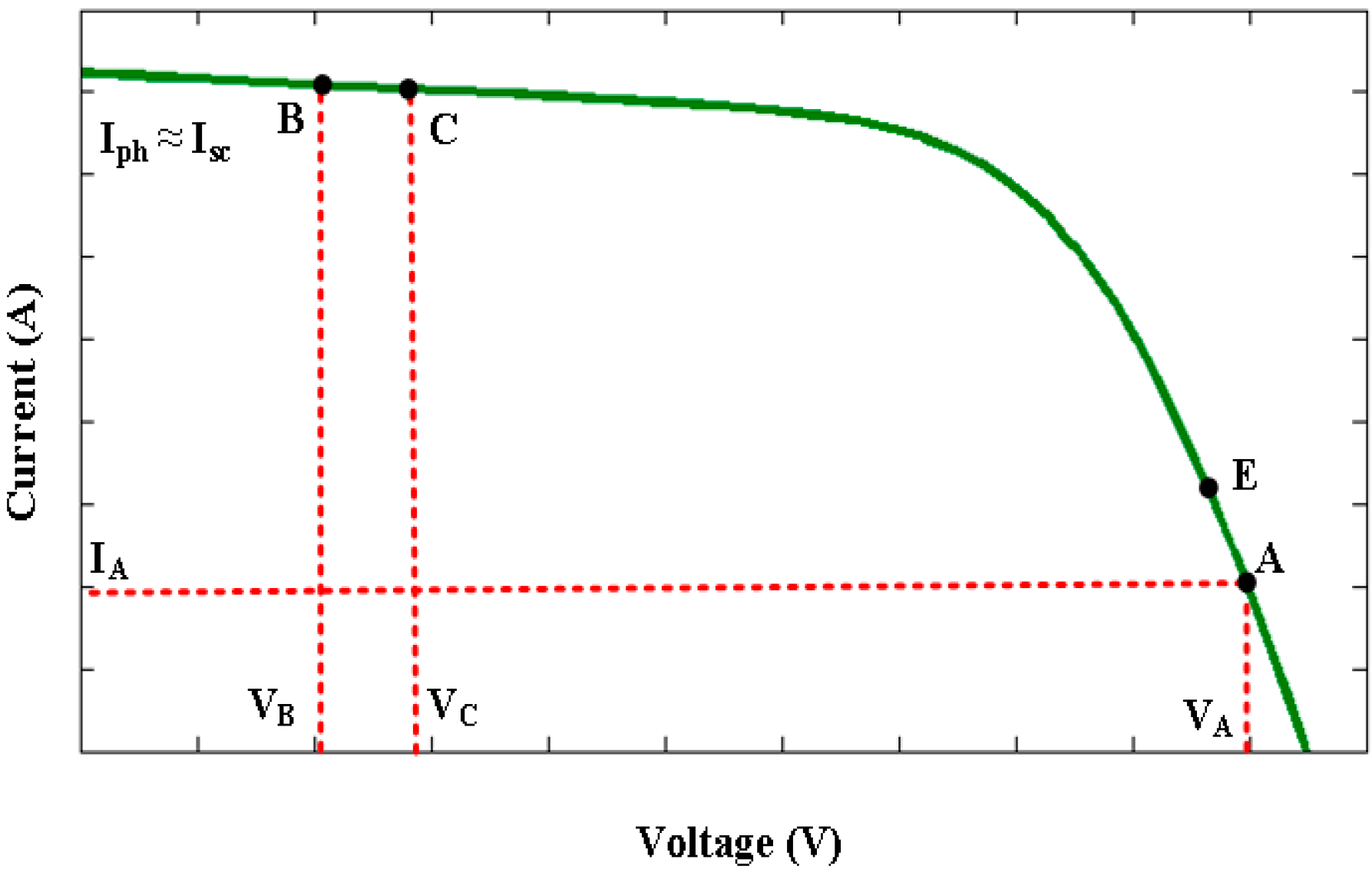

Low initial degradation green curve results in more economical pv installations.

Frequent intermediate measurements are required to distinguish one degradation profile from the other.

To calculate the annual degradation percentage of solar panels we ll need to know the annual kwh production of the system.

After the system s useful life your panels can go on producing electricity.

This rate of decline is called solar panel degradation rate.

For amorphous silicon solar cells the dangling bond density will be dramatically increased by light induced degradation the swe.

The mean average degradation rate was 0 8 to 0 9.

Manufacturers typically guarantee 90 of the panels production until the first ten years.

This can be measured and recorded using a photovoltaic production meter.

For monocrystalline silicon the most commonly used panel for commercial and residential pv the degradation rate is less than 0 5 for panels made before 2000 and less than 0 4 for panels made after 2000.

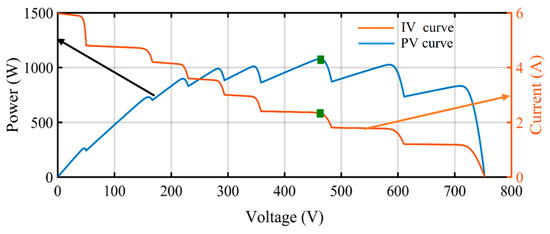

Degradation is defined as the loss of power produced relative to the rated power.

After ten years that percentage drops back to 80 for the remaining 15 20 years.

_Effect_In_Pv_Modules_Figure_5.jpg)